An OT Door is more than just a way in and out—it’s a frontline defence in maintaining sterility. When designed with medical rigor and proper fitment, operation theatre door details can significantly reduce risk of pathogen ingress. Attention to materials, seals, framing and integration with wall sections is essential to prevent contamination.

A high-quality operation theatre door, particularly when configured as a single or double leaf, helps maintain the pressure zones and airtight boundaries that are essential to a sterile surgery environment. This blog examines door specifications, hygiene factors, and layout integration to show how door design enhances infection control in modular OT Setup.

Why OT Door Design Matters for Clean Environments

Doors are moving parts and weak links if not sealed and matched properly. Poor framing or mismatched finishing between ot door and Clean Room Doors wall panel gaps gives microorganisms a foothold. OT doors often interface with operation theatre equipments, staff flow, and pressure differentials, making their hygiene impact doubly critical.

Key Design Features for Infection Control

Flush Door Panel Construction

- OT doors are built with a thick, rigid core made of honeycomb material using CFC-free polystyrene, enclosed between stainless steel laminate faces. The outer surface is finished with an antimicrobial silver ion powder coating for hygiene control.

- The panel is framed with stainless steel profiles, creating a uniform, flush surface with surrounding Clean Room Doors panels. This eliminates dirt traps and reduces microbial accumulation points.

- Flooring on either side of the door must be perfectly aligned to prevent any pressure leakage that can compromise the sterile environment.

Airtight Fit and Pressure Barrier

- Honeycomb core makes each door impervious to microbial ingress, supporting clean air zones.

- Door seals must integrate with adjacent wall panels to hold positive pressure and maintain sterile airflow.

Hardware Quality

- Heavy‑duty stainless steel handles with a gloss finish allow cleaning without wear.

- Cylindrical locks and hydraulic closers enable smooth, quiet closing—avoiding impact that might break seals.

Frame and Vision Panel

- Use SS 304 grade frames: resistant to moisture and disinfectants.

- Vision panels of 5 mm toughened glass allow visibility while preserving enclosure integrity.

- Radiation‑proof door variants include a 1 mm lead sheet and lead‑based vision pane when required.

Single vs Double Leaf or Sliding

- Single or double leaf Options for operation theater doors provide varying widths and flow rates.

- Double leaf variants minimize traffic and door openings by enabling the rapid movement of trolleys and equipment.

- For airtight performance, sliding doors (where space permits) also employ flush-fit construction and seal design.

How Door Design Helps Infection Protocols

- Antimicrobial surfaces in OT Door and frame drastically reduce microbe survival on high-touch areas.

- Airtight seal ensures that airflow control systems (HEPA or laminar flow) aren’t compromised when doors open.

- Proper door width and opening style reduce total door cycles, limiting pressure fluctuations.

- Stainless steel handles and lock surfaces are easy to disinfect and meet hygiene standards.

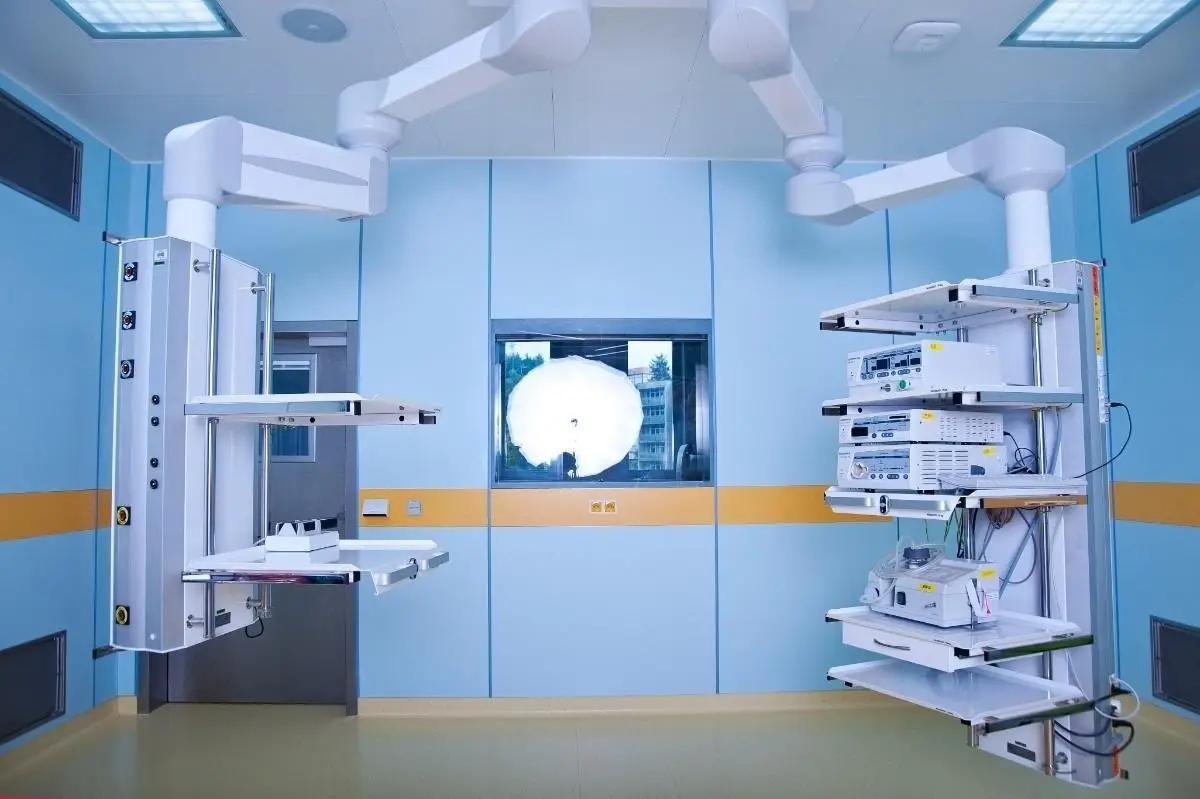

Integration with Modular OT Setup & Other OT Equipment

Doors must flange onto OT Equipment layouts and line up with modular wall panels to maintain clean zones.

In conjunction with surgical lights, pass boxes, laminar ceiling units, and surgeon control panels, the door design contributes to the maintenance of infection control procedures.

Pass boxes (static or dynamic) further reduce contamination risk by handling sterile transfers without staff exiting or door opening frequently.

Benefits of Correct Door Specification

Benefit | Impact on Infection Control |

Antimicrobial laminates | Prevents microbial growth on door surface |

Airtight flush seal | Maintains clean airflow and pressurization |

Durable SS hardware | Ensures sanitizable surfaces without wear |

Double‑leaf option or sliding style | Reduces door cycling and maintains OT pressure stability |

Workspace Metal Solutions' Role in OT Door Design

Top-notch OT Door designs for modular operating rooms are provided by Workspace Metal Solutions. Single leaf, double leaf, and sliding doors are constructed with thick panels featuring an antibacterial coating, stainless steel laminates, and a honeycomb polystyrene core. Controlled pressure zones and consistent wall-to-door integration are ensured through SS 304-grade frames and precise fitting. Vision panels and circular hardware meet hygiene standards while allowing visibility and functional ease.

Workspace Metal Solutions provides full OT Setup integration across OT Equipment, wall, ceiling and door systems. Each component works in harmony to preserve sterility, support accreditation compliance and improve surgical workflows across modular theatres.

Frequently Asked Questions (FAQ)

Standard specification is 60 mm thickness with 52 mm honeycomb polystyrene core (CFC‑free) and antimicrobial coated stainless-steel faces. This supports airtightness and microbial resistance.

Double leaf works well for high‑volume traffic or moving equipment; single leaf works for standard throughput. Both must support flush fit and full seal with wall panels.

Yes, 5 mm toughened glass panels can be included for visibility. For radiation‑protected areas, a 1 mm lead sheet and lead‑based glass are added.

Critical. Stainless steel SS 304 frame with precise leveling and sealing with wall panels ensures no microbial ingress and stable pressure zones.

Not if designed flush with proper seals and rails. They reduce physical movement and limit disturbance to airflow patterns