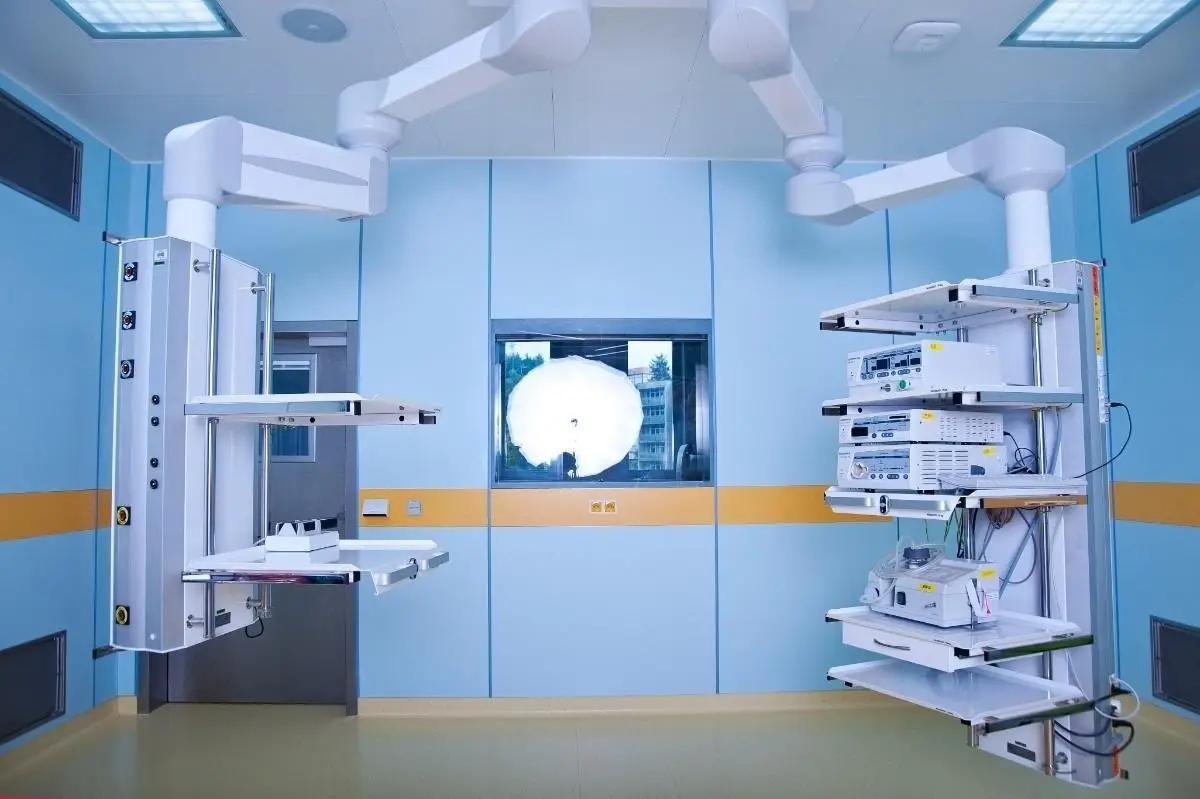

In the realm of modern hospitals, the modular operation theatre (OT) has become the cornerstone of advanced surgical care. These carefully designed environments prioritise sterility, efficiency and patient safety. Among the various OT equipment that are integral to these setups, the pass box stands out as a crucial component. Understanding its role and importance is essential for any healthcare facility that aims to optimise its operating room setup.

Understanding the Pass Box

A pass box, sometimes referred to as a transfer hatch, is a specialized OT equipment used to move goods between regions with varying degrees of cleanliness without letting airborne pollutants enter the cleaner area. pass box enables the safe and effective transfer of surgical tools, medicines, and other essential supplies into and out of the sterile environment in a modular operating room. By maintaining the sterile field’s integrity, this process lowers the chance of postoperative infections.

Key Features of a Pass Box

- Interlocking Doors: Pass box equipped with two doors on opposite sides, designed with an interlocking mechanism that prevents both doors from being opened simultaneously. This feature ensures that the cleanroom remains uncompromised during the transfer process.

- Material Composition: Pass box usually made of stainless steel and provide longevity and simplicity of cleaning, which are crucial for upholding hygienic standards in a surgical setting.

- Airflow Control: Some OT equipment (pass box) designed with built-in HEPA filters and unidirectional airflow systems to further minimize the risk of contamination during the transfer of materials.

The Importance of Pass Box in Modular Operation Theaters

- Infection Control: Serving as a barrier against contaminants is a pass box main purpose. The risk of airborne germs entering the operating room is greatly decreased by the pass boxes, which limit the need for staff to enter and exit the sterile area often.

- Operational Efficiency: Workflow in the operating room is streamlined using pass boxes. Because materials may be moved swiftly and safely without interfering with the sterile environment, surgical staff can obtain necessary tools or supplies without delays.

- Cost-Effectiveness: By minimizing contamination risks and the associated costs of managing infections, pass boxes contribute to the overall economic efficiency of hospital operations.

- Compliance with Standards: Pass boxes ensure that the facility satisfies necessary safety and quality criteria by conforming to international healthcare standards and guidelines.

Integration with Other OT Equipment

In a modular operation theater, the pass box functions in harmony with other critical components:

- Laminar Air Flow Systems: These systems control the airflow within the operating room to prevent contamination. The pass box complements this by controlling the entry and exit points for materials, ensuring that the laminar flow remains undisturbed.

- Air Handling Units (AHUs): In the OT, AHUs control the temperature, humidity, and air quality. The pass box supports these units by reducing the amount of outside air pollutants introduced, therefore preserving ideal environmental conditions.

- Surgeon Control Panels: These panels allow surgeons to control various aspects of the operating room environment. The integration of pass boxes ensures that any necessary materials can be transferred without manual intervention, allowing the surgical team to focus on patient care.

Selecting the Right Pass Box Manufacturer

Choosing a reputable pass box manufacturer is crucial for ensuring the quality and reliability of this essential equipment. Factors to consider include:

- Compliance with Standards: Manufacturers should adhere to international standards and guidelines, ensuring that their products meet the stringent requirements of modern hospital environments.

- Customization Options: Each hospital has its own requirements. Pass boxes can be customized to meet the unique needs of the facility by a manufacturer that provides bespoke solutions.

- After-Sales Support: Reliable technical support and maintenance services are essential for the long-term functionality of pass box. Manufacturers who offer comprehensive after-sales support ensure that any problems can be resolved promptly.

F.A.Q.

The pass box facilitates the transfer of materials between areas with varying cleanliness levels without compromising the sterile environment of the operating room.

By minimising the need for personnel movement in the sterile area, the pass box reduces the risk of airborne contaminants entering the operating room, thereby enhancing infection control measures.

Key features include interlocking doors, durable stainless-steel construction, and airflow control mechanisms such as built-in HEPA filters.

Yes, many manufacturers offer customization options to tailor the pass box to the unique requirements of a hospital’s operating room setup.

Pass boxes work in conjunction with systems such as laminar airflow units and air handling units to maintain a sterile environment and optimize operating room efficiency.